Projecting

& Engineering

Projecting

& Engineering

Projecting

& Engineering

Offer of our services

we can provide you with support at every stage of the project

Projecting

Projecting piping, components and devices

Engineering

Engineering services for various industry branches

Related activities

Project engineering, preparing technical documentation

We create lasting values for your company

Our company has been on the market since 2014. We focus on engineering services for the energy, chemical, petrochemical and food industries, however we also deliver high value-added solutions for other industry branches.

As part of our business, we provide our clients with a complete portfolio of services related to

developing new project documentation, or revising existing technical documentation

according to the actual conditions on the construction site.

11

years

on the market

6 countries

with our projects implemented

Our services

We specialize in design and engineering. Our team of qualified experts will provide your company with a complete range of services in the field of engineering.

In order to achieve optimum results, we use both our long-year professional experience and the latest software tools. We deal with complex projects and can always adapt to individual requirements of each client.

Consulting and advisory services are an inseparable part of each of our projects. Especially in the initial phase of a project, it is always necessary to identify suitable individual solutions for the respective client, to perform an analysis and optimization of existing processes and systems

Engineering services for the energy, chemical, petrochemical and food industries.

- Preparation of project documentation, assembly and production documentation.

- Conceptual design

- Spatial design

- Technology selection

- Basic design

- Implementation project

- Device specification

- Actual status plan

Dilatation-stress analysis of pipelines

(statics, dynamics)

Pipeline strength calculations

Calculations based on internal pressure in the design of piping classes, verification of wall thickness of piping components, especially according to EN 13941, EN 13480-3, ASME B31.3, etc.:

- checking pipe movements and deflections

- pipe stress analysis

- checking of flange loads

- determination of loads acting on pipe supports (the data serve as a basis for the structural engineer)

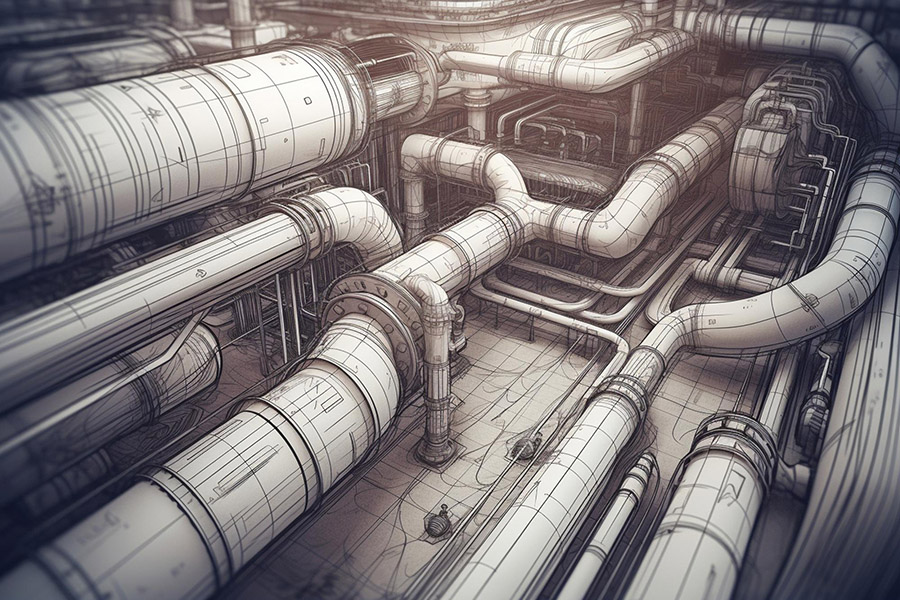

3D scanning of operating facilities

Thanks to 3D scanning technology, we are able to capture the current state of the respective operating facility. Compared to the method of manual surveying of pipeline routes, the efficiency, accuracy and speed of the work is of particular advantage. By scanning pipeline routes, equipment or structural units, we obtain highly accurate basis for the preparation of the relevant project documentation. The time required is thus reduced, especially in case of projects with short delivery times. Time savings enable the client to benefit from cost savings as well.

Using a 3D scanner is beneficial e.g. in the case of more complex structural units, where manual surveying would be very time-consuming.

1.

Conceptual design

Includes the design of the dimensional requirements of the main equipment, its layout plan, description of the operating and process conditions, interconnections between devices. Documentation scope:

- Spatial layout plan of the main facilities

- Basic pipe calculations (diameter and wall thickness)

- Location of equipment within systems and facilities

2.

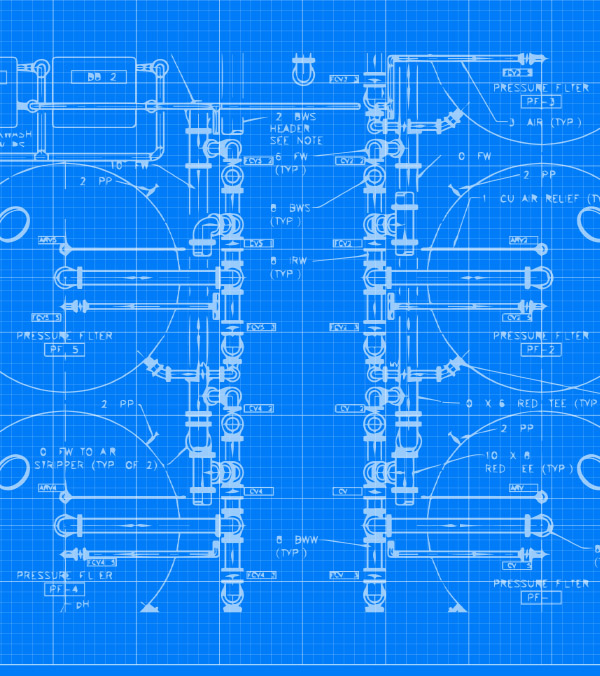

Basic project

It consists of technical reports, drawings, list of materials and equipment, specification of all important parts. Documentation scope:

- General layout

- Base plan for each instrument

- Basic processes and measurements (P&ID drawings) and process flow diagrams (PFD diagrams)

- Technical report and process description of all units

- 2D and 3D drawings of structural units and isometric designs

- Piping layout design

3.

Implementation project

Final phase of project documentation. Documentation scope:

- Technical reports

- P&ID drawings

- Detailed 2D and 3D drawings

- Isometric drawings

- Assembly drawings

- Piping list

- Valve list

- List of instrumentation

- Measurement list

- List of supports

- List of connection points

- Welding plan

- Static calculation (pressure parts, steel and concrete structures)

- Purchasing specification